【Offline procurement consulting】

Phone:15335258233;

Email:engforlife-mkt@efl-tech.com

【product introduction】

Gelatin Methacryloyl (GelMA) can be quickly photo-crosslinked into hydrogel through UV and visible light in the presence of photoinitiator. GelMA hydrogel combines the characteristics of both natural and synthetic biomaterials. With the three-dimensional (3D) structure, it is suitable for cell growth and differentiation. GelMA hydrogel has excellent biocompatibility and cell-responsive properties, such as providing suitable cell adhesion sites and proteolytic degradability. Therefore, it often is used as a replacement for artificial basement membranes or other natural collagen hydrogels. In addition, GelMA hydrogel also has good mechanical properties.

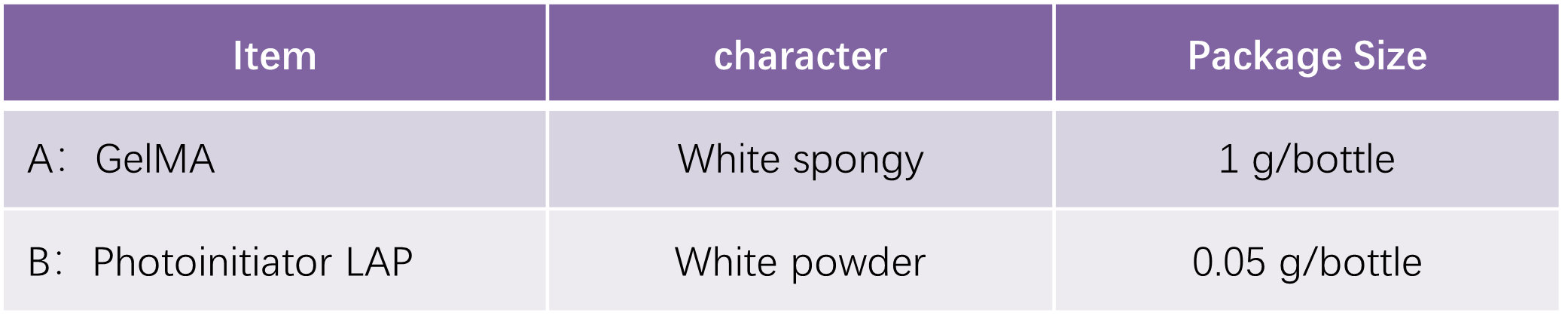

【Item】

【Applications】Cell culture, bio 3D printing, tissue engineering, etc.

【Storages】Dry kit: room temperature, 3 months; 4℃, 12 months; -20℃, 18 months.

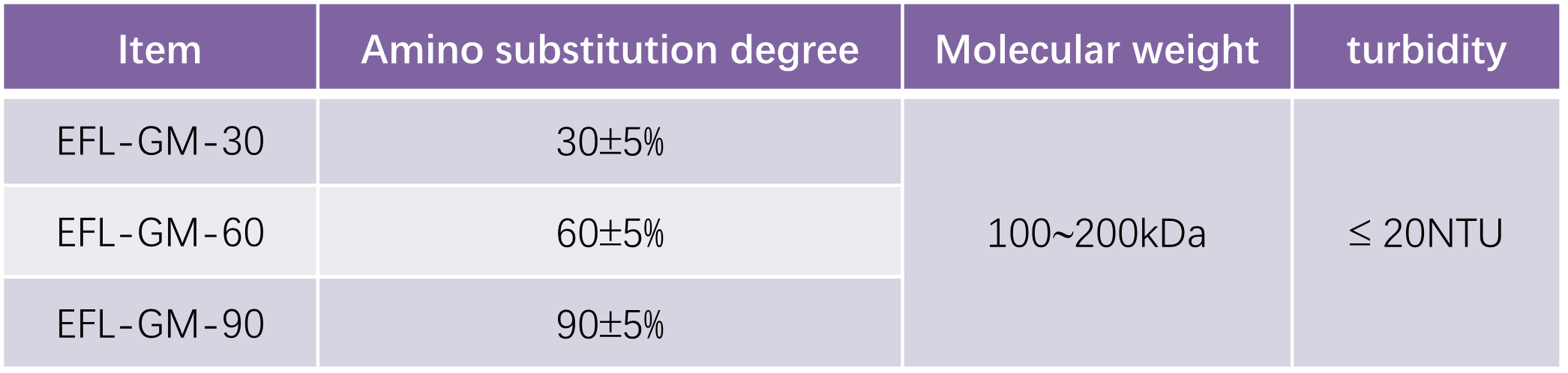

【HNMR】

Synthesis reaction mechanism of GelMA and NMR spectrum of GM30/60/90

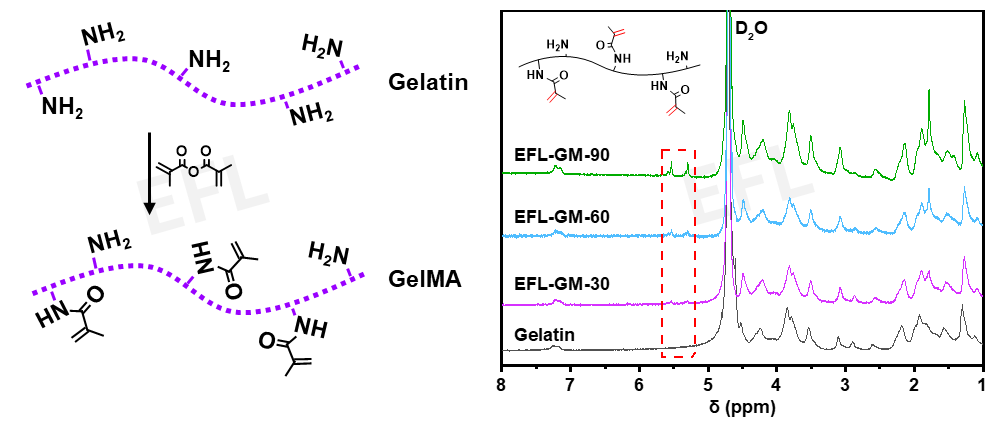

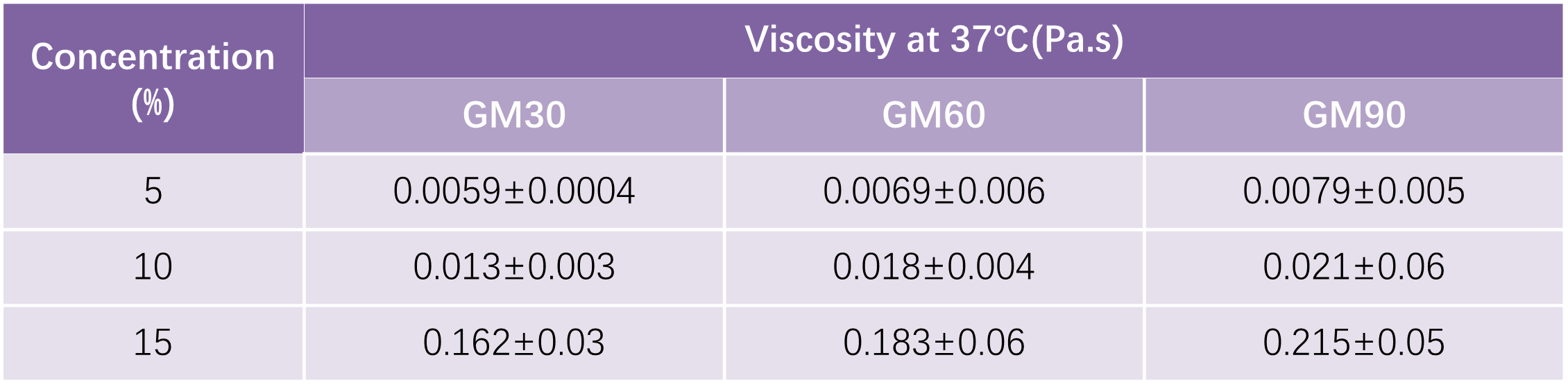

【Viscosity】Rheological test: viscosity (shearing rate: 10rad/s, 37℃)

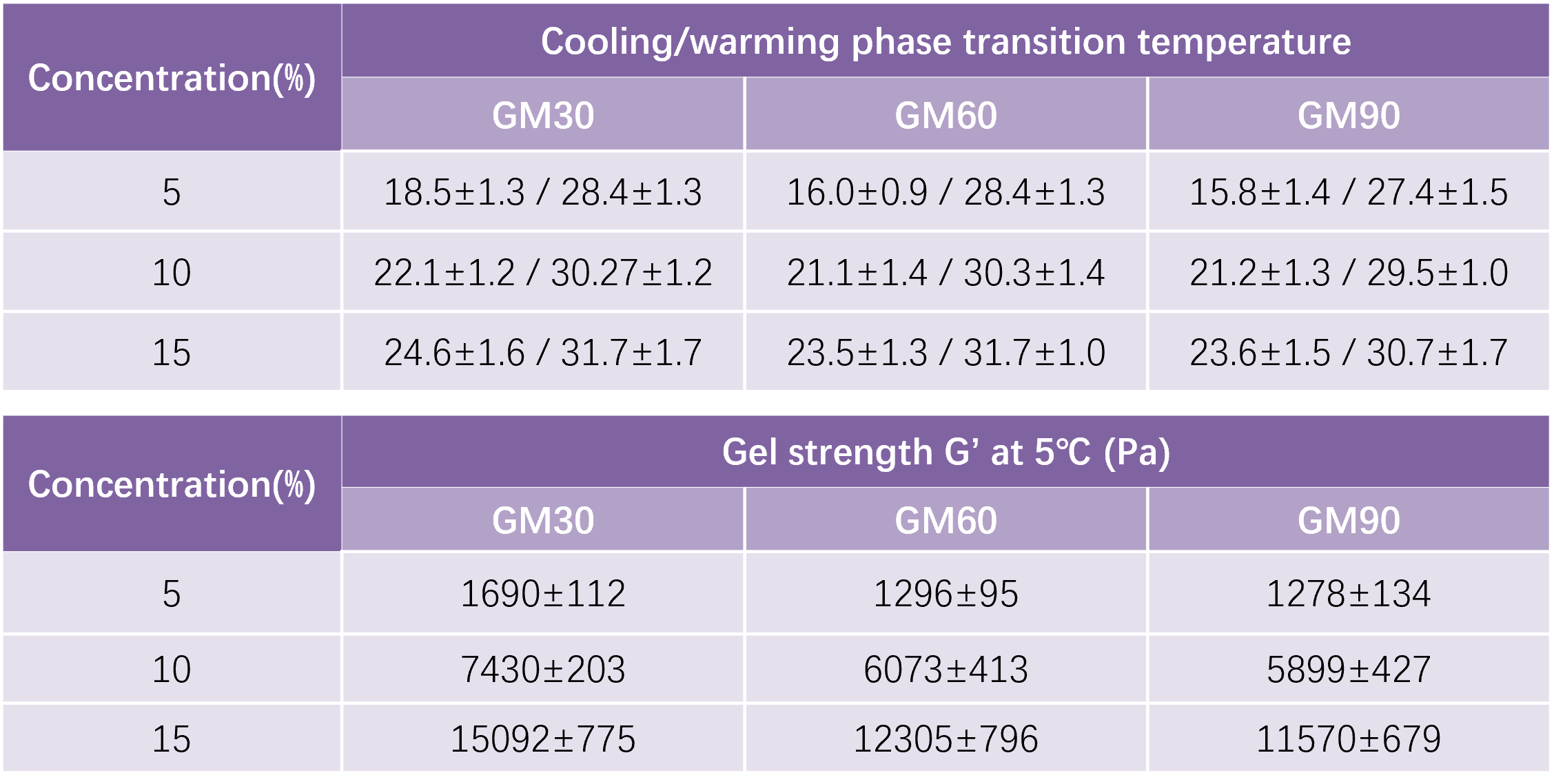

【Thermosensitivity】Rheological test: cooling/warming phase transition temperature and gel strength at 5℃ (oscillation temperature scan: 40 ℃→4 ℃→40 ℃, 5℃ /min, strain 1%, angular rate 5rad/s)

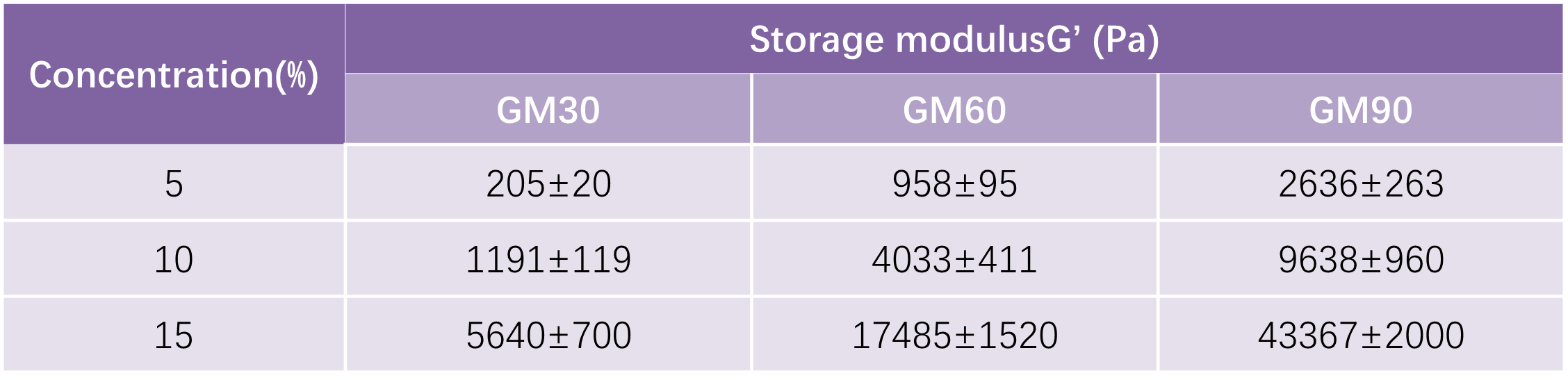

【Storage Modulus】Rheological test: photo-crosslinking process and final gel storage modulus (oscillation time scan: strain 1%, angular rate 5rad/s; light source: 405nm, 30mW/cm², 30s)

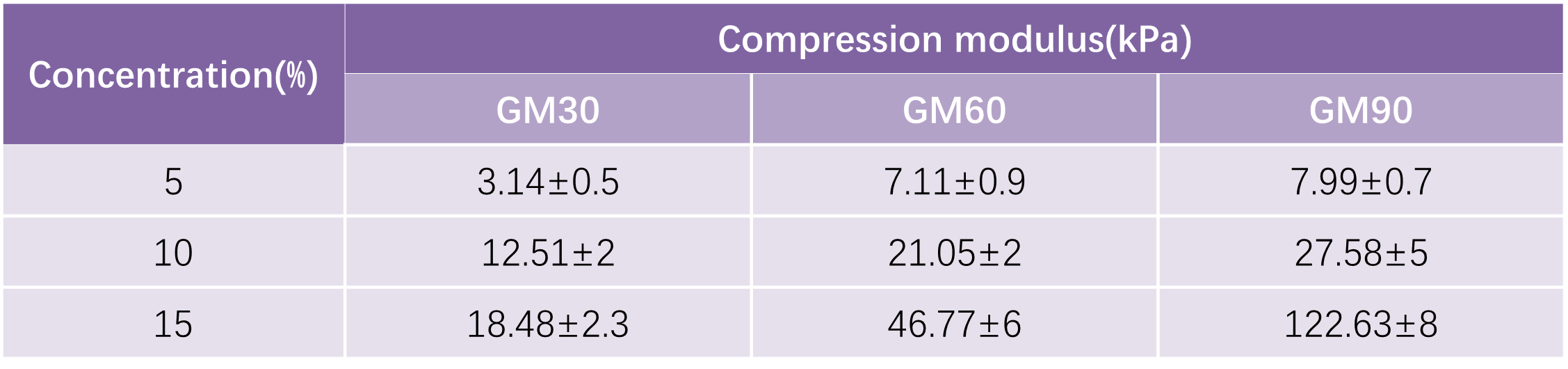

【Compression Modulus】Compression modulus of 3 types GelMA with different concentrations: EFL-LS-1601-405 light source curing 30s

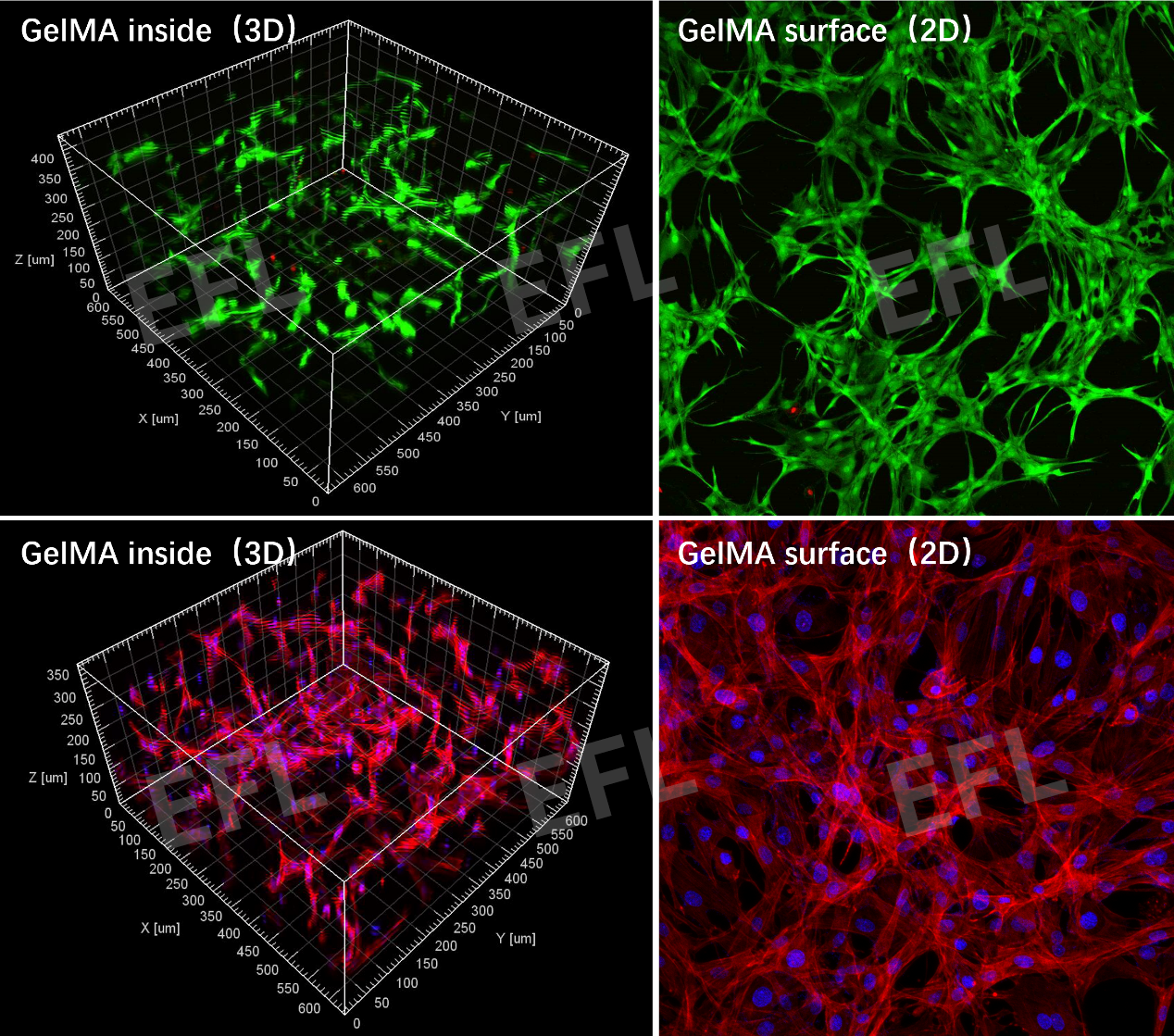

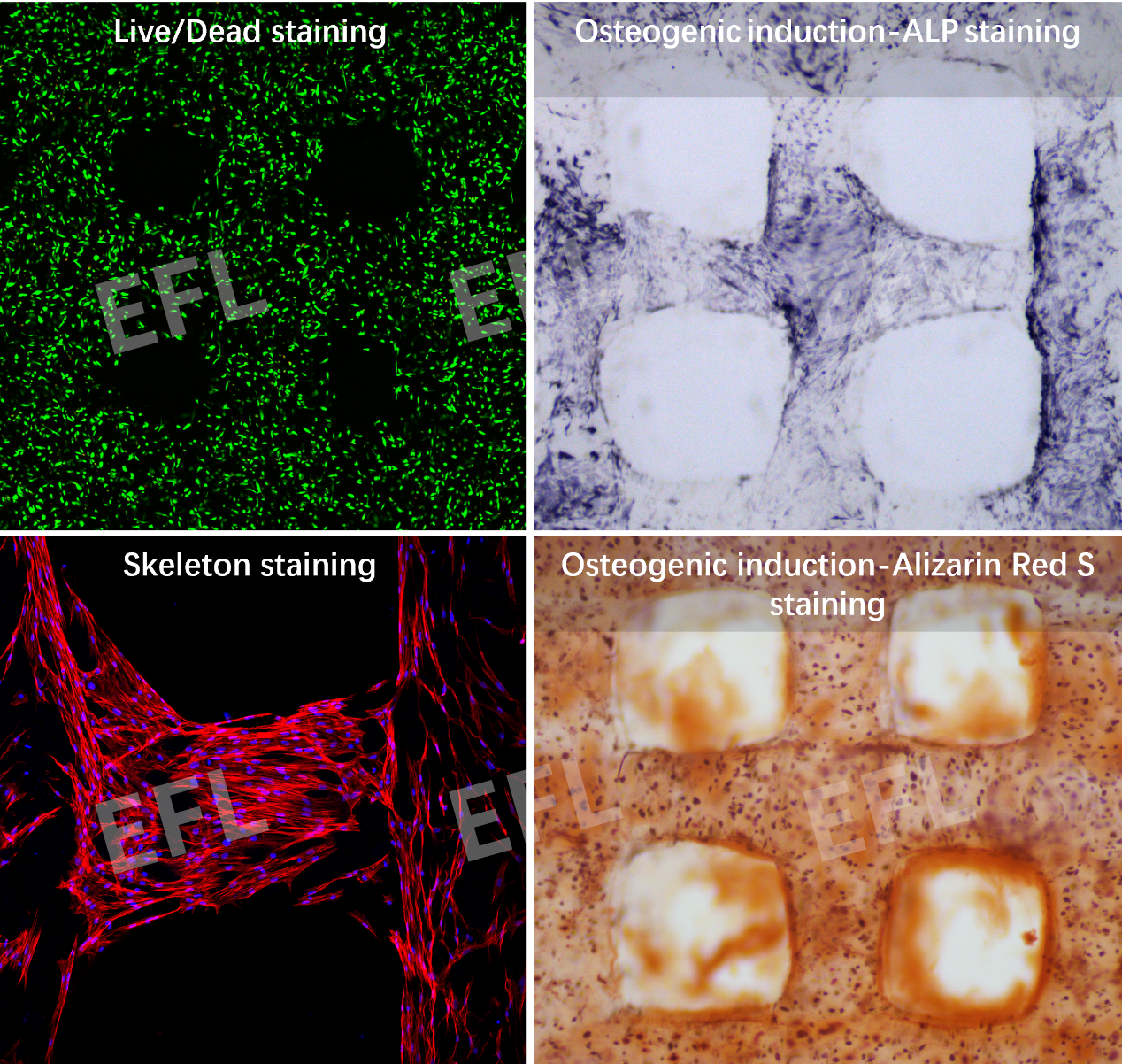

【Biocompatibility】 GelMA has been widely used for the 2D/3D culture of stem cells, cancer cells, endothelial cells, nerve cells, and other types of cells. The survival rate of cells co-cultured with GelMA is >90% and the cells are well functionalized.

Bone marrow mesenchymal stem cells (BMSCs) cultured on the surface and inside of GelMA

Biocompatibility characterization of 3D-printed GelMA scaffold

【Q&A】GelMA Hydrogel Use FAQ

Gelatin methacryloyl (GelMA) has been widely used in various biomedical applications, such as 3D cell culture, tissue engineering, biological 3D printing, and other research fields due to its suitable biological properties and tuneable physical characteristics. GelMA products developed by the EFL team have the advantages of stable batches, professional service, and so on. They are well-received and recognized by domestic and international researchers. In order to help users to better use the EFL-GM series hydrogel products, the EFL team has compiled the following high-frequency questions related to the use of GelMA, which are useful for reference.

Q1: How much solution can be prepared with 1g of GelMA?

A: The recommended solution concentration range is 5%-30% (w/v). So, in theory, 1g of GelMA can prepare 3.3-20mL of working solution. Normally, 10-20mL of working solution can be prepared with 1g of GelMA. The LAP initiator is included in the kit and no longer needs to be purchased separately.

Q2: What amino substitution degree does GelMA have? What type of GelMA should be chosen for inoculating cells on the surface of GelMA and for mixing cells into GelMA for 3D culture? What type of GelMA should be used for 3D printing?

A: ① Three commonly used types(GM30, GM60, and GM90) of GelMA are available in stock, with the degree of amino substitution of 30%, 60%, and 90%. GM30, GM60, and GM90 can all be used in cell culture. Under the same conditions, the higher the degree of substitution, the stronger the cured hydrogel. The optimum degree of substitution and strength of the hydrogel for different cell growth varies. It is recommended that users do a preliminary experiment with three types of hydrogel respectively to select the most suitable type, concentration, and cross-linking conditions.

② The cells inoculated on the surface of all types of GelMA works well. For the selection of types to mix cells into GelMA for 3D culture, the commonly used types and parameters are recommended as follows: 5% GM30 (w/v), EFL-LS-1601 portable curing light source irradiating 30- 60s, 5% GM60 (w/v), EFL-LS-1601 portable curing light source irradiating 15-22s.

③ GM30, GM60, and GM90 can all be used in extrusion printing and can be combined with other materials to make composite hydrogel extrusion printing. The degree of substitution can be selected according to the strength of the scaffold. If cell-loaded extrusion printing is required, cell growth conditions should be considered at the same time. If you do projection light curing 3D printing with high precision, GM90 is the preferred choice, with excellent forming and cell-carrying properties. PS: If users have additional GelMA material performance requirements such as high strength, precision two-photon printing or low-temperature sensitivity, etc. They can consult EFL technicians individually for a better solution.

Q3: How do I store GelMA? GelMA solution solidified at -4℃, is it denatured?

A: Dry kit: room temperature, 3 months; 4℃, 12 months; -20℃, 18 months. Sterile solution: 4°C (in dark), 7 days; -20℃ (in dark), 6 months. GelMA solution with a low degree of substitution is recommended for use on the spot, repeated freezing and thawing of the solution will affect the performance of the product. GelMA solution is temperature-sensitive and can form a reversible physical gel at low temperatures. It is normal for GelMA to solidify when stored at room temperature or in a refrigerator in dark, and it can be restored by heating.

Q4: Can the thick GelMA solution be filtered? If so, is the filtration loss large? Is it hard to filter at high concentrations? Is there any other way to sterilize? Can it be sterilized by autoclaving at 121°C?

A: It can be filtered and de-bacterized by a 0.22-micron sterile filter head. Filtration loss is proportional to the concentration, the higher the concentration the higher the loss of the same type of GelMA solution. The filtration loss rate of 5% (w/v) is less than 5%, and that of 10% (w/v) is less than 10%. When using a concentration of ≤ 10% (w/v), 0.22um filtration is the most practical option At concentrations >10% (w/v), high-concentration liquids are more viscous and not easily filtered, and the loss is large. Selecting a pasteurization method or purchase15% (w/v) sterile GelMA solution (Catalog No.: EFL-S-GM-30/60/90) is the better way to solve the above problem. GelMA belongs to polypeptide materials, which can not be autoclaved at high temperatures (121). This will easily damage the molecular structure and prevent curing.

Q5: Which type of GelMA is suitable for the animal experiment?

A: All types can be used in animal experiments, the specific selection of types and concentrations depends on the experimental requirements. If a slower degradation of the material is required, the GelMA with high concentration and a high degree of substitution corresponding to high Young's modulus is selected, and vice versa. If cells are to be mixed with the materials, both the growth and survival conditions of the cells should be taken into account. GelMA has been widely used in all kinds of tissue repair and regeneration (bone repair, cartilage repair, nerve regeneration, myocardial repair, etc.), wound dressing, loading, and controlled release of various drugs and growth factors and other biomedical research fields. The mechanical strength of different biological tissues can be simulated by adjusting the concentration and curing conditions of hydrogels. The reference values of Young's modulus range of GelMA are shown in the table below.

Q6: Can GelMA be used to load exosomes or ECM for cell culture? Can it be cured? Any recommended type?

A: Yes. EFL has many customers who have researched this. The specific type depends on your strength requirements and the characteristics of the cells.GM30, GM60, and GM90 are all used by customers for cell culture. You can do pre-experiments first to find out what conditions are suitable for the cells.

Q7: When GelMA solutions are placed on slides or Petri dishes, the material tends to stick to the substrate after curing, what can be done to avoid or minimize adhesion?

A: You can use the anti- adhesive membrane of EFL(Catalog No.: EFL-GRF series). The anti- adhesive membrane is suitable for the non-destructive stripping of various commonly used hydrogels and resins. If you are doing 3D cell culture, you can try the 3D culture of the EFL customized curing ring kit (Catalog No.: EFL-SCR-3D series), which can improve the metabolism of cells in the gel and facilitate the later characterization operation.

Q8: How to extract cells from GelMA for WB and PCR? Trypsin does not seem to separate the cells from GelMA.

A: You can use the GeMA lysate of EFL (Catalog No.: EFL-GM-LS-001) to degrade GelMA and extract cells. GelMA can be rapidly degraded by the lysate within 0.5-2h and the cell integrity and viability are well maintained. The extracted cells can be further subcultured, and also can be used in protein or RNA extraction.

Q9: Why do the cells grow well on one side and poorly on the other side of a GelMA mesh-loaded scaffold prepared by 3D printing? Shouldn't the whole scaffold be growing similarly?

A: EFLer's practical experience has shown that when scaffolds are co-cultured with cells placed in plate wells, the cells do not grow as well on the bottom side of the sticker plate of the scaffold as on the top surface. However, when the scaffold is cultured in suspension with the cells in the medium, there is no significant difference in the growth of the cells on each surface of the scaffold. You can culture the printed cell-loaded scaffolds on the 3D cell culture accessories (Catalog No.: EFL-SCR-3D series) developed by EFL. The whole scaffold can be suspended in the medium to enhance the metabolism of cells in the scaffold and improve the situation you encounter.

Q10: Why do some of the cells grow well and some of the cells grow poorly in the blocks I made in the same experiment?

A: This may be related to your curing operation. In the curing process, you need to maintain the same curing conditions, light intensity, illumination distance, and duration. It is recommended that you use the portable curing light source independently developed by EFL (Catalog No.: EFL-LS-1601-405). Compared with the traditional flashlight source, this light source has the advantages of stable light intensity, fixed illumination distance, and controllable illumination time, which can well eliminate the differences between samples.

Q11: I have 3D printed several model structures using GelMA, but the material is transparent and the physical pictures don't look good in any way, is there a good way to take pictures?

A: Hydrogels can be dyed with different colors of dye to make the structure of hydrogels more recognizable. EFL has launched anti-diffusion hydrogel dyes (Catalog No.: EFL-DYE -ND), which are available in five colors: red, green, blue, yellow, and purple. The dye has a good anti-diffusion ability and can visually present different hydrogel forms. It can be applied to the coloring observation of self-healing hydrogels, suspended printing hydrogels, injectable hydrogels, and micro-channel hydrogels irrigation.

Q12: I want to wrap a layer of cell-loaded GelMA hydrogel on the surface of a 3D printed scaffold and then do immunofluorescence staining. How can I photograph the distribution of cells on the scaffold without fluorescence?

A: You can choose to wrap the cultured cells directly with fluorescent GelMA (Catalog No.: EFL-GM-RF/GF/BF series), or label the ordinary GelMA with the alkene-coupled fluorescent dye (Catalog No.: EFL-DYE-UF-ENE series). Select the fluorescence color that does not conflict with your immunofluorescence, and use the fluorescence emitted by GelMA to outline your printed scaffold structure.

Copyright ©2022 Copyright: EFL-Tech Co.,Ltd, Suzhou, China 苏ICP备19070244号-1

Technical support: Wanhe Technology